Features

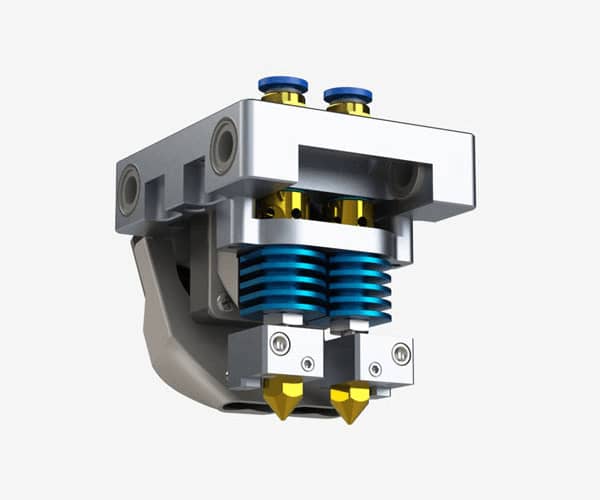

We are the first one to publish a 350°C ultra-high temperature nozzle to the mass market. We proud to ant possess the exclusive patent of this nozzle. This nozzle allows the print of a variety of filaments. The blue cooling sink can efficiently cool down the nozzle. Furthermore, the nozzle height can also be micro-adjusted. We are able to accept customization from single to double and triple head.

We exclusively research and develop the extruder feeding system and guide rail, which support high-speed printing. Its printing accuracy can reach high to 0.05mm, and it allows for steady filament extrudsion thus reducing blockage.

The whole-steel body ensures stability when printing and it also extends the usage period of the machine greatly. Its optimization and cooperation of the overall structure ensure sustainable and efficient operation. The first batch of CreatBot 3D printers has been working for 9 years and more than 30,000 hours.

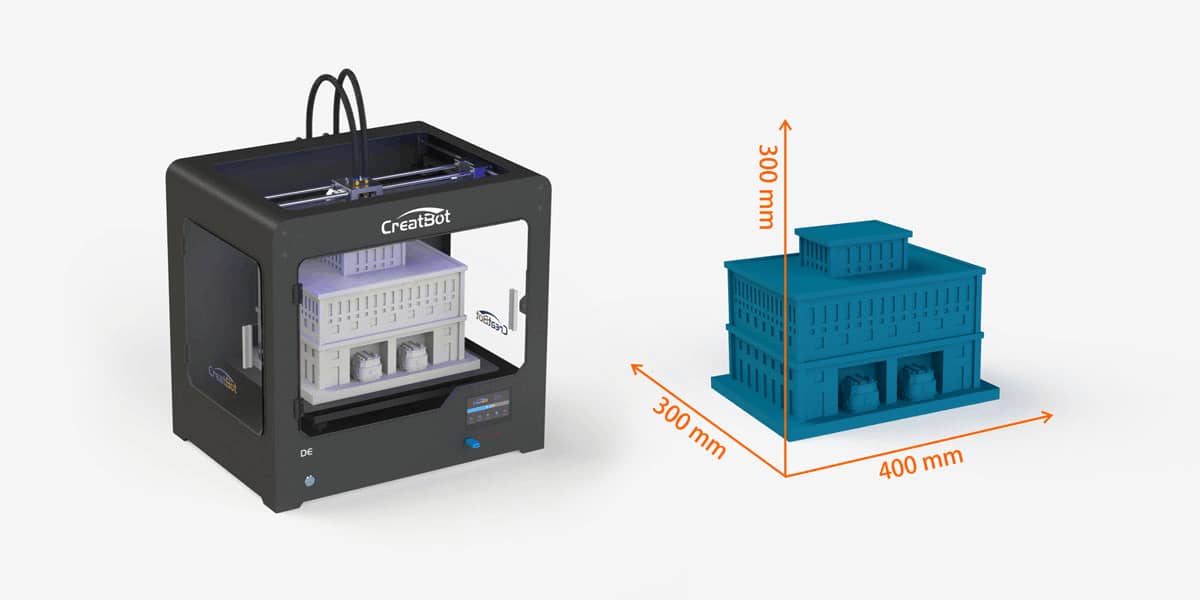

We provide variety of printing sizes for you reference. The largest build volume is 5 to 20 times bigger than it of other ordinary 3D printers in noadays market.

The printer will memorize the current position and save that information in its database. In an event of an outage, the platform will automatically be lowered and the filament withdrawn.Upon power restoration, the printer will continue to print from the last stopped point prior to the outage The printer will avoid any invalid prints by stopping the print. A warning will be indicated when the filament runs out.

The printer is equipped with a borosilicate glass platform. This allows for high thermal efficiency. For an added precaution, you can turn off the hot bed automatically after a specified number of layers by changing the setting parameters.

The printer has an all-english-menu touch screen which is easy and user friendly. Shortkeys such as warming and print minimizes the number of buttons to press at one point in time.

Technical specs

| Printing | |

| Print Technology | Fused Deposition Modeling |

| Build Volume | 400*300*300 mm (DE) |

| 400*300*520 mm (DE Plus) | |

| * 3 nozzles build width:380mm | |

| Number of Nozzles | Double (Max.3) |

| Resolution | 0.05 mm |

| Layer Resolution | 0.05 mm |

| Filament Diameter | 1.75 mm (3.0/2.85 mm optional) |

| Filament Compatibility | PLA, ABS, Carbon Fiber, PTEG, etc. |

| Nozzle Diameter | 0.4 mm(0.3 0.5 0.6 0.8 1.0 mm) |

| Print File Type | STL, OBJ, AMF, Gcode |

| Speed | |

| Best Printing speed | 45 mm/s |

| Max. Printing speed | 200 mm/s |

| Electrical | |

| Power Requirements | 100V-110V or 200V-240V / 50-60Hz (Depending on your country’s default voltage) |

| Max. Power | 360 W |

| Screen | 4.3” full color touch screen, multi-language |

| Control Chip | ATmega 2560 |

| Storage Media | U Disk |

| Connectivity | USB |

| Software | |

| Software Bundle | CreatWare, Simplify 3D, Cura, Slice 3r, etc |

| Supported File Types | STL,OBJ,AMF |

| Operating Systems | Win7/8/10, MacOS |

| Temperature | |

| Ambient Operating Temperature | 15-32 ℃ |

| Max. Nozzle Temperature | 260 ℃ |

| Max. Bed Temperature | 100 ℃ |

| Special Function | |

| Outage Restored | Save data when power is off |

| Filament Detection | Pause printing when filament run out |

| Automatic Shut-down | Turn off the power automatically when printing is complete |

| Mechanical | |

| Construction | Power-Coated Steel, Aluminum Casting for Motion Components, POM etc |

| Build Plate | Glass Panel |

| Build Plate Leveling | Factory Leveled, Adjust Manually |

| Extruder | Geared motor (1:10 rate) |

| Stepper Motors | 1.8°Step Angle with 1/16 Micro-stepping |

| X Y Positioning Precision | 12.7 μm |

| Z Positioning Precision | 1.25 μm |

| Size & Weight | |

| Product Dimensions & Weight | 590*430*560 mm 35 kg (DE) |

| 590*430*780 mm 42 kg (DE Plus) | |

| Packing Size & Weight | 720*560*670 mm 45 kg (DE) |

| 720*560*870 mm 55 kg (DE Plus) | |